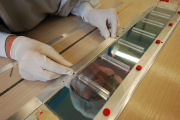

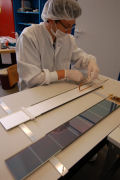

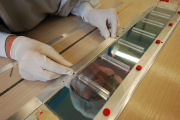

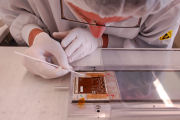

Cleaning the template

|

Selecting the 1st sensor

|

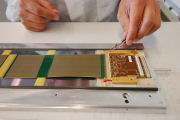

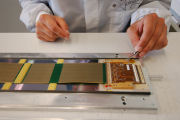

Placing the 1st sensor

|

Selecting the 2nd sensor

|

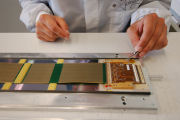

Placing the 2nd sensor

|

Selecting the 3rd sensor

|

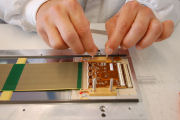

Placing the 3rd sensor

|

Placing the 4th sensor

|

Placing the 5th sensor

|

Placing the 6th sensor

|

Selecting the 7th sensor

|

Placing the 7th sensor

|

Selecting the hybrid

|

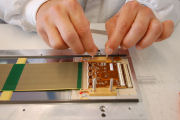

Placing the hybrid

|

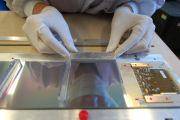

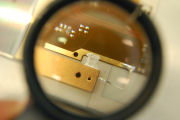

Checking the sensor alignment

|

Correcting the sensor alignment

|

Checking again

|

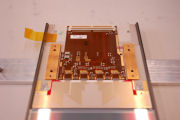

Placing the module under the CMM

|

Measuring the sensor alignment

|

Measuring the sensor alignment

|

Preparing the glue

|

Mixing the glue

|

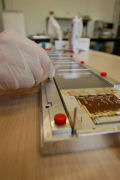

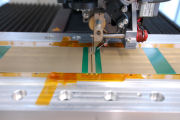

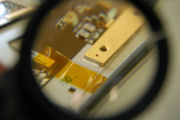

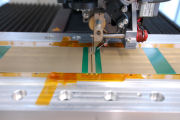

Transfering the glue to the roller

|

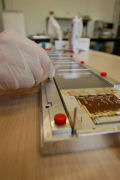

Transfering the glue to the stencils

|

Transfering the glue to the sensor edges

|

Transfering the glue to the sensor edges

|

Transfering the glue to the sensor edges

|

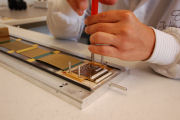

Placing the 1st rail

|

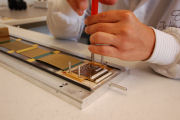

Pushing the 1st rail onto the sensor edges

|

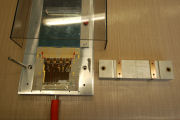

Checking the position of the 1st rail

|

Checking the position of the 1st rail

|

Placing the module under the CMM

|

Measuring the sensor alignment

|

Placing the copper blocks on the mounting tool

|

Fixing the copper blocks on the mounting tool

|

Ready for mounting onto the hybrid

|

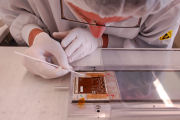

Glueing the copper blocks onto the hybrid

|

Weighting them down for the glue to cure

|

The most important task...

|

...cleaning the stencils

|

Applying a copper strap for the hybrid grounding

|

Applying a copper strap for the hybrid grounding

|

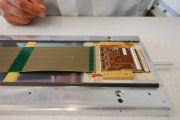

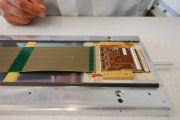

Hybrid with the copper ground strap

|

Applying silver glue for the ground connection

|

Ground connection between hybrid and copper block

|

Applying silver glue for the ground connection

|

Ground connection between hybrid and copper block

|

Mounting the bias voltage cable

|

Mounting the bias voltage cable

|

Mounting the bias voltage cable

|

Hybrid end of the bias voltage cable

|

Applying silver glue for the connection to the sensor

|

Applying silver glue for the connection to the sensor

|

Bias voltage connection on the back of the sensor

|

Applying silver glue for the connection to the hybrid

|

Bias voltage connection on the back of the hybrid

|

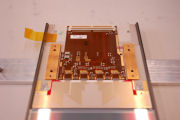

Ready for burn-in

|

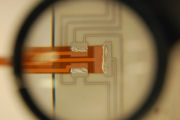

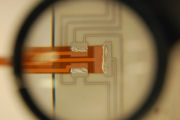

Kapton interconnect on the bond station

|

Positioning the bond head

|

Positioning the bond head

|

Bonding the two pieces of the interconnect

|

Bonds on the ground strip

|

Bonds on the signal strips

|

Pulling a broken bond

|

Three bonded interconnects

|

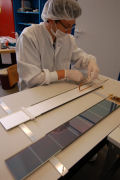

Rolling out the glue

|

Transfering the glue to the Kevlar caps

|

Glueing a Kevlar cap over the bonds

|

Weighting the Kevlar caps down for the glue to cure

|

Placing the positioning tool

|

Fixing the positioning tool

|

Checking the positioning tool

|

Placing the interconnect cable

|

Self-adhesive tape on the sensor end

|

Fixing the interconnect cable on the sensor

|

Placing a weight for glue curing

|

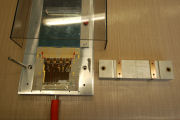

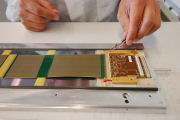

Screws, positioning pins and copper blocks

|

Placing the hybrid and copper blocks

|

Placing the washers

|

Placing the screws

|

Placing the positioning pins

|

Fixing the screws

|

Done

|

Waiting for the glue to cure

|

Waiting for the glue to cure

|